How to Choose a Contract Manufacturer For Supplements & Functional Foods

April 20, 2020

This post is for anyone trying to choose their ideal contract manufacturer. If you’ve determined your 5 Ps and target market and found a void in the marketplace that you can uniquely fill, you are well on your way. Now it’s time to carefully find and vet the right contract manufacturer with the right equipment, competencies and service levels to turn your ideas into reality.

Before we start, it’s important to note that a brand must run at least 2500 units. This is bare bones. If a brand doesn’t have the funds or marketing expertise to run 2500 units, we advise delaying until that is possible. If your brand already has other product winners, then contract manufacturers (co-mans) will often do you a favor and run smaller numbers of units to accommodate your market test. Many co-mans have 5000 unit minimums.

Just like most companies, contract manufacturers started with a few core customers in a particular sector. Some started in sports nutrition, others in MLM. Some co-mans have giant capacity, run on slim margins and need volume to keep the business running. Others specialize in certain sectors and accommodate smaller run sizes.

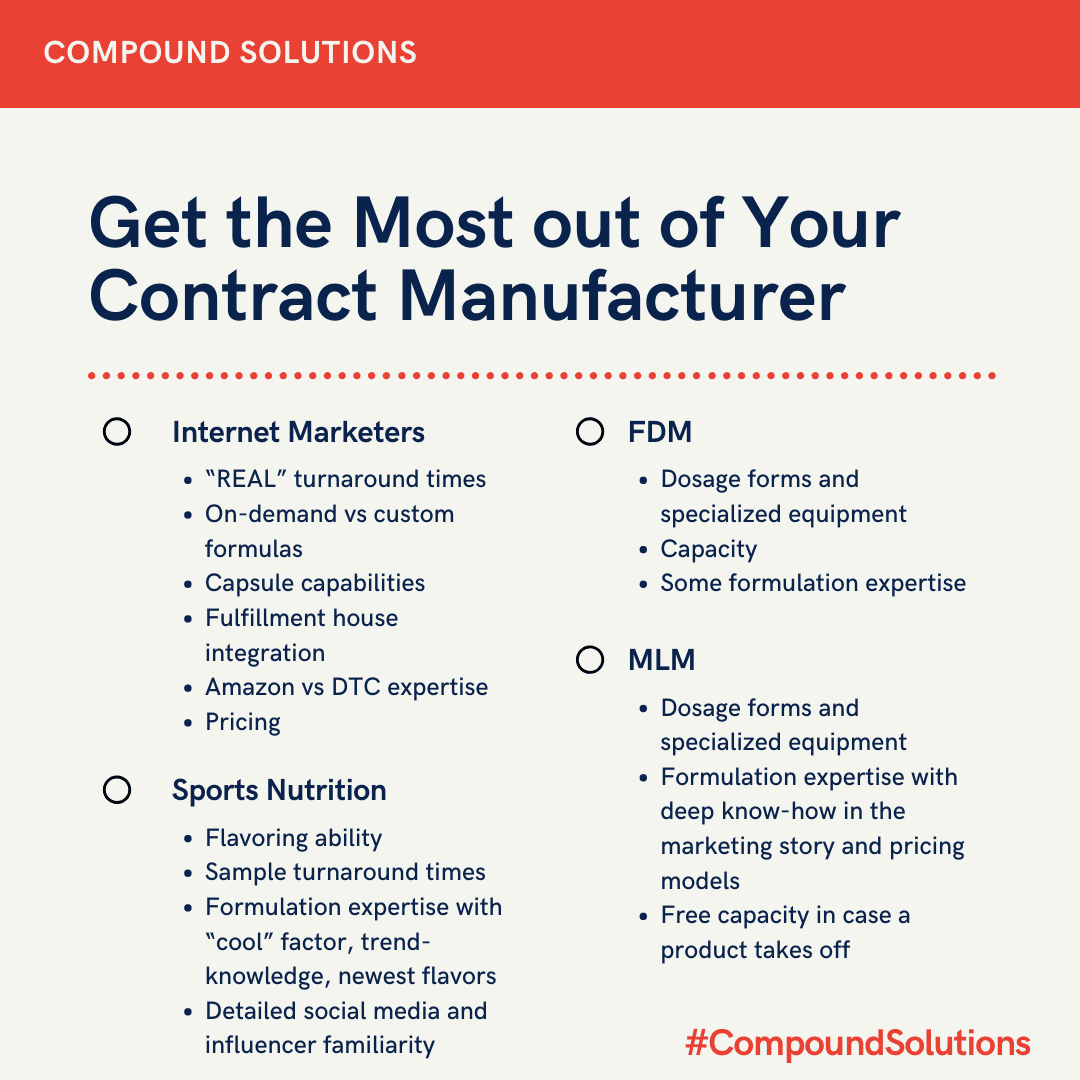

We believe identifying the contract manufacturer who truly knows your sector is deeply important. When you go to a co-man about sports nutrition, but they’ve been running multivitamins for FDM players for the past 10 years, there can be communication difficulty. To ease communication and get the most out of your co-man experience, here are a few important points to consider for each sector:

Just like most companies, contract manufacturers started with a few core customers in a particular sector. Some started in sports nutrition, others in MLM. Some co-mans have giant capacity, run on slim margins and need volume to keep the business running. Others specialize in certain sectors and accommodate smaller run sizes.

We believe identifying the contract manufacturer who truly knows your sector is deeply important. When you go to a co-man about sports nutrition, but they’ve been running multivitamins for FDM players for the past 10 years, there can be communication difficulty. To ease communication and get the most out of your co-man experience, here are a few important points to consider for each sector:

Types of Contract Manufacturers

Just like most companies, contract manufacturers started with a few core customers in a particular sector. Some started in sports nutrition, others in MLM. Some co-mans have giant capacity, run on slim margins and need volume to keep the business running. Others specialize in certain sectors and accommodate smaller run sizes.

We believe identifying the contract manufacturer who truly knows your sector is deeply important. When you go to a co-man about sports nutrition, but they’ve been running multivitamins for FDM players for the past 10 years, there can be communication difficulty. To ease communication and get the most out of your co-man experience, here are a few important points to consider for each sector:

Just like most companies, contract manufacturers started with a few core customers in a particular sector. Some started in sports nutrition, others in MLM. Some co-mans have giant capacity, run on slim margins and need volume to keep the business running. Others specialize in certain sectors and accommodate smaller run sizes.

We believe identifying the contract manufacturer who truly knows your sector is deeply important. When you go to a co-man about sports nutrition, but they’ve been running multivitamins for FDM players for the past 10 years, there can be communication difficulty. To ease communication and get the most out of your co-man experience, here are a few important points to consider for each sector:

Internet Marketers

- “REAL” turnaround times

- On-demand vs custom formulas

- Capsule capabilities

- Fulfillment house integration

- Amazon vs DTC expertise

- Pricing

Sports Nutrition

- Flavoring ability

- Sample turnaround times

- Formulation expertise with “cool” factor, trend-knowledge, newest flavors, …

- Detailed social media and influencer familiarity

FDM (Food, Drug, Mass)

- Dosage forms and specialized equipment

- Capacity

- Some formulation expertise

MLM

- Dosage forms and specialized equipment

- Formulation expertise with deep know-how in the marketing story and pricing models

- Free capacity in case a product takes off and you need to quickly increase volume